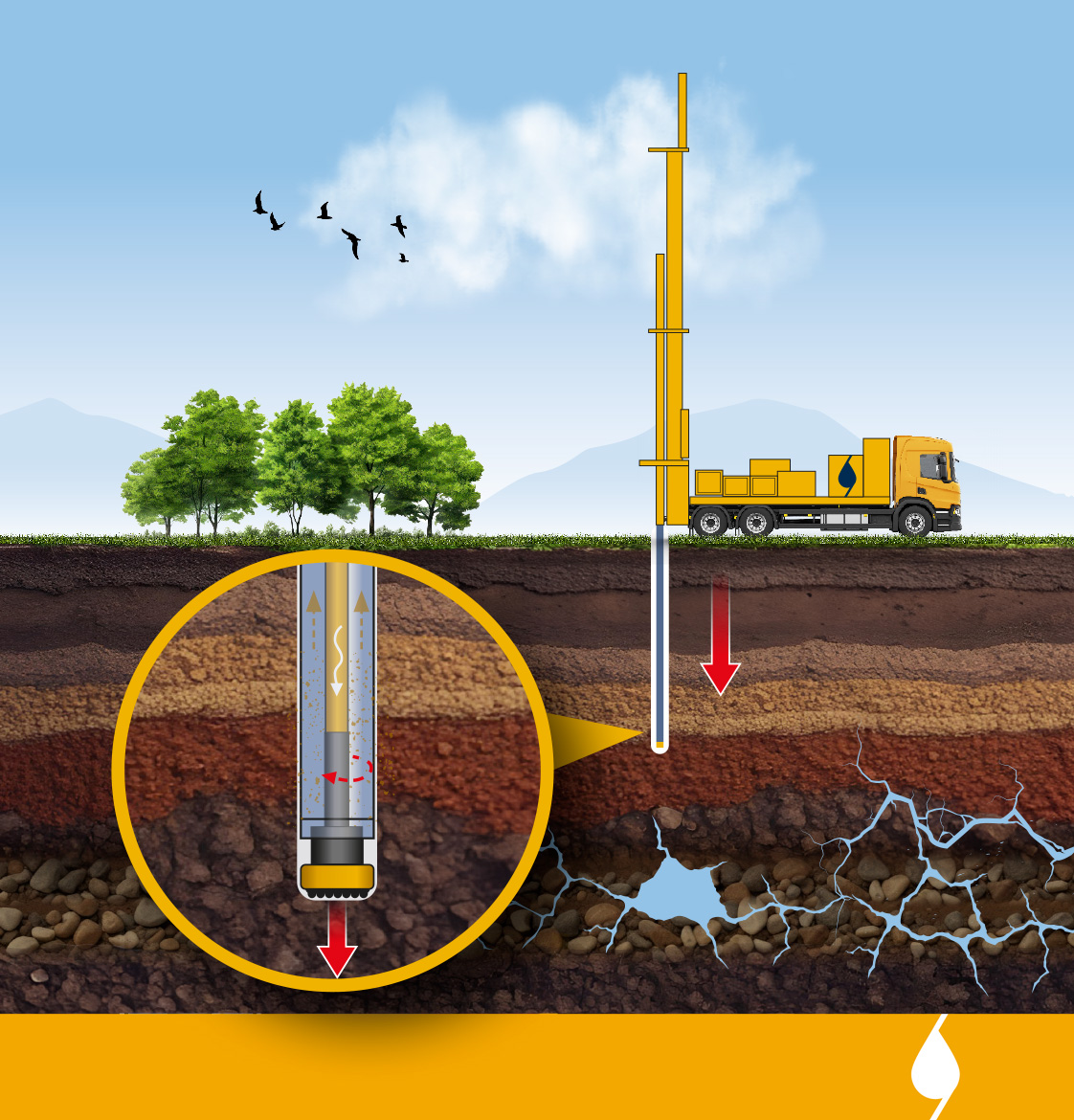

VERTICAL DRILLING

Josep M. Casellas

VERTICAL DRILLING MANAGER

VERTICAL DRILLING SYSTEMS

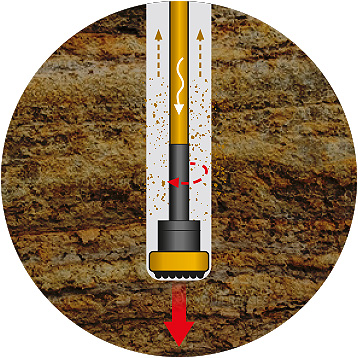

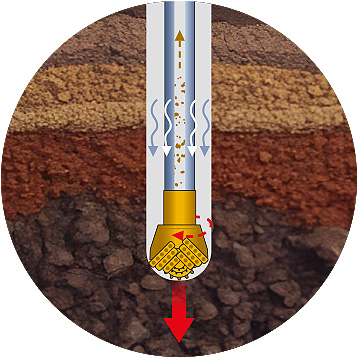

Rotary percussion

The rotary percussion system used in the vertical drilling method is structured around the use of compressed air to drive the hammer or drilling tool while creating a circulation and transport of cuttings out of the borehole.

DEPTH:

– Maximum lengths: up to 900m

DIAMETER:

– Maximum diameter: 610mm

GROUND:

Drilling system suitable for drilling consolidated ground with granite, limestone, sandstone, making it a fast and efficient drilling system.

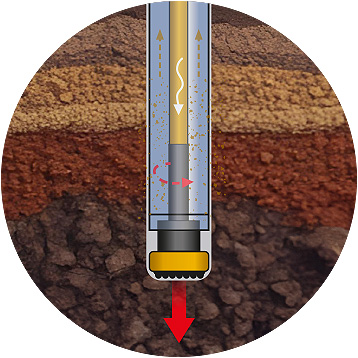

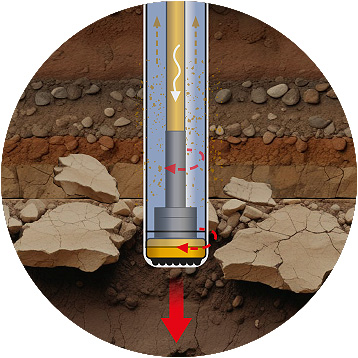

Double head

The dual head system involved in the vertical drilling method allows simultaneous drilling and casing in unconsolidated and difficult-to-drill ground.

This method of drilling entails the use of a drilling rig with two independent rotating heads, one driving the drill rod and borehole, the other driving the temporary working pipe.

This system ensures the maximum stability of the walls and minimum soil disturbance.

It is the perfect drilling method for water abstraction in alluvial aquifers.

DEPTH:

– Maximum lengths: up to 200m

DIAMETER:

– Maximum diameter: 610mm

GROUND:

Drilling system suitable for drilling in unconsolidated ground.

Reverse-circulation rotation

The reverse-circulation rotation system involved in the vertical drilling method entails reverse rotation placing the drilling tool at the end of the rod and inserting drilling fluid and removing cuttings through the borehole itself.

This system ensures the maximum stability of the walls and minimum soil disturbance.

This system is mainly used for deep boreholes in poorly consolidated soils such as clays, clayey sands, loams and gravels, among others.

DEPTH:

– Maximum lengths: up to 900m

DIAMETER:

– Maximum diameter: 450mm

GROUND:

Drilling system suitable for drilling in poorly consolidated ground.

Symmetrix®

The Symmetrix system applies a double vertical drilling technique that consists of exerting the rotational and thrust force of the ground cutting tool simultaneously with the casing feed, cooling and cleaning the assembly by means of water injection.

This technique is designed for deep boreholes in poorly consolidated soils such as clays, clayey sands, loams and gravels, among others.

DEPTH:

– Maximum lengths: up to 900m

DIAMETER:

– Maximum diameter: 450mm

GROUND:

Drilling system suitable for drilling in unconsolidated soils

Uses

- Groundwater abstraction

- Water table replenishment as part of civil engineering works

- Geothermal energy use

- Decontamination of aquifers

- Injection wells

- Geological reconnaissance surveys and geothermal research

- Cathodic protection

- Drilling in confined spaces

Other vertical drilling solutions

- Well maintenance and rehabilitation

- Sealing of existing wells and/or special cementation

- Testing and video inspections

- Permit processing

- Hydrogeological studies